Products & Technologies

Burner system

Active regeneration by Hybrid Burner system

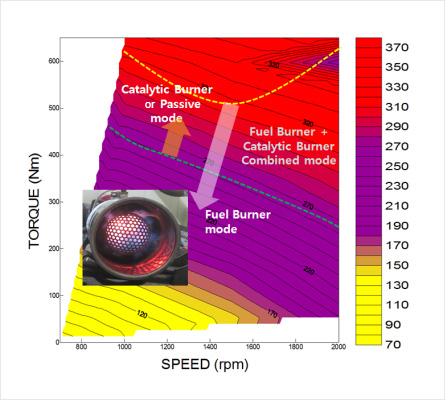

The hybrid burner system has two operating modes depending on the engine running condition

Catalytic Burner Mode

- Fuel injected in front of pre-catalyst(DOC) when the exhaust temperature exceeds 250℃(in High Torque and High RPM condition)

- Flameless combustion(Exothermic reaction) process occurs

- Exhaust temperature can be increased up to 450℃ for FBC aided regeneration or up to 650℃ for O2 regeneration

Flame Burner Mode

- Fuel can be injected while the exhaust temperature is below 250℃(in Low Torque and Low RPM condition)

- Ignited by pre-heated glow plug and forms visible flame

- Exhaust temperature can be increased up to 450℃ for FBC aided regeneration or up to 650℃ for O2 regeneration

- Can be operated in low oxygen concentration until 12~14%

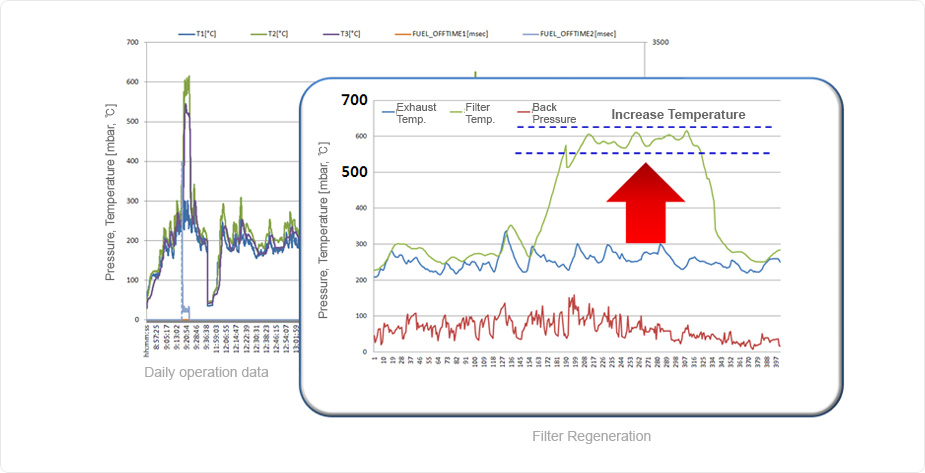

The hybrid burner system raise the exhaust temperature up to target temperature of 450℃ or 650℃ in any operation condition and successfully burn out accumulated soot in the filter.

Increase Temperature by Hybrid Burner ②

Hybrid burner system can safely regenerate filters, and precisely controls the right timing for both Diesel burner and Catalytic burner.

Increase Temperature by Hybrid Burner ①