Products & Technologies

FBC

FBC aided regeneration technology

The FBC aided active regeneration provide us with two advantages.

The one is the relatively low regeneration temperature(450℃) in comparison with O2 regeneration(650℃) and accordingly the fuel injection amount can be minimized. (approximately 50%)

The other one is the short regeneration time in comparison with the other technologies. Since the FBC provides better contact between the catalyst and the carbon/soot particles, regeneration time can be significantly shortened. (approximately 50%)

The one is the relatively low regeneration temperature(450℃) in comparison with O2 regeneration(650℃) and accordingly the fuel injection amount can be minimized. (approximately 50%)

The other one is the short regeneration time in comparison with the other technologies. Since the FBC provides better contact between the catalyst and the carbon/soot particles, regeneration time can be significantly shortened. (approximately 50%)

FBC developed by CleanEarth

Features of CleanEarth’s FBC

- Iron(Fe) soap

- Fe concentration of 6% in solution

- Recommended FBC dosing rate is 25ppm,Fe for Euro2, 3 engine

- Density : Same as diesel fuel

- Operating temperature : -40°C ~ +80°C

Solubility in Diesel

Operating principle of FBC-type DPF

- ① FBC injected into fuel tank immediately after every refueling event(target concentration in fuel : 400ppm, solution)

- ② Fuel containing iron(Fe) enters into the engine cylinder once engine starts.

- ③ After combustion process PM mixed with Fe nano-particles is emitted from engine.

- ④ Emitted Fe particles and PM are collected in DPF filter.

- ⑤ Due to the catalytic function of dispersed Fe particles the collected PM burns out at low temperature(450℃)

- ⑥ By igniting burner and/or injecting fuel in front of hot pre-catalyst the exhaust temperature rises up to 450℃ and then the filter can be regenerated effectively during short time.

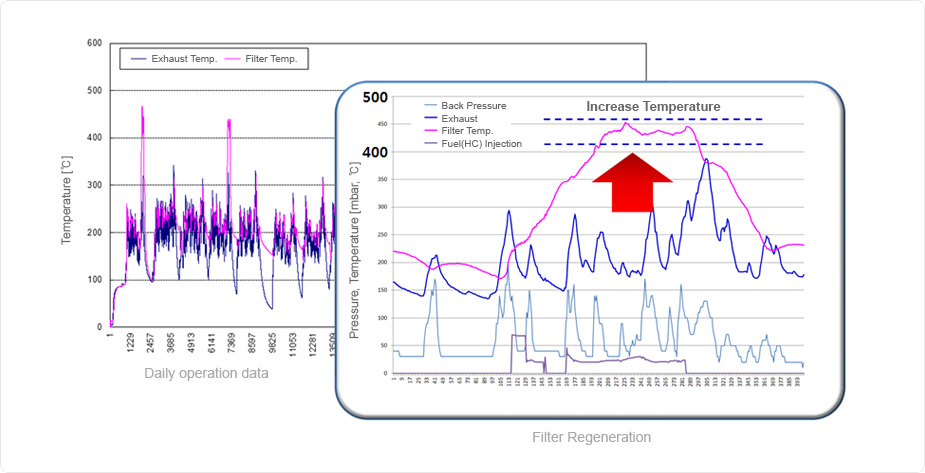

The system can safely regenerate the filter through precise controlling of fuel injection and exhaust temperature up to the target temperature.

Regeneration strategy of FBC aided active DPF